China wholesale Sheet Metal Fabrication - Laser Cutting Machining Punched Bending Welding Stamping Plate Parts – Huachen

China wholesale Sheet Metal Fabrication - Laser Cutting Machining Punched Bending Welding Stamping Plate Parts – Huachen Detail:

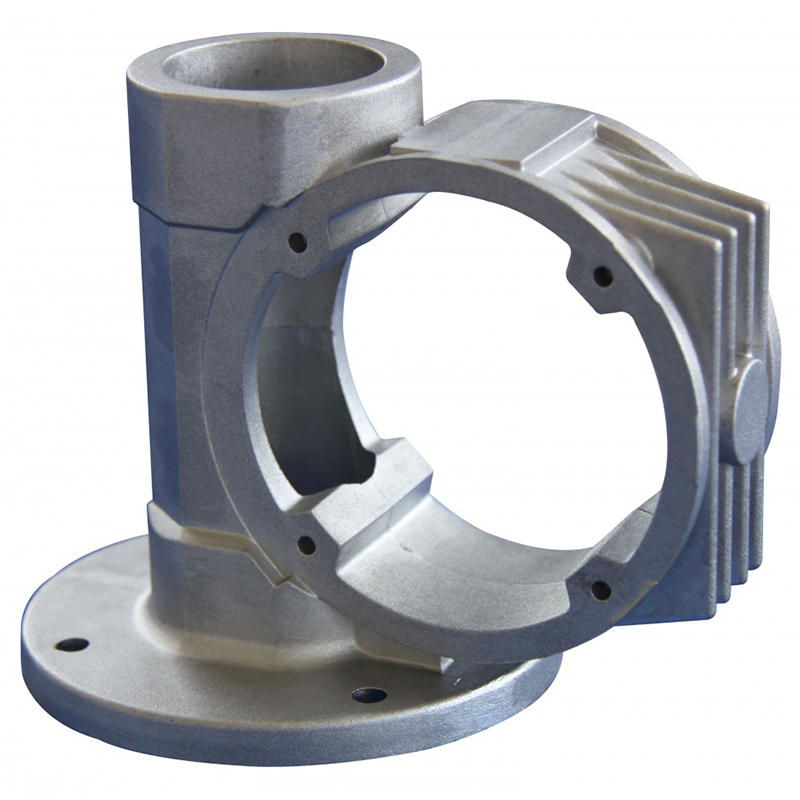

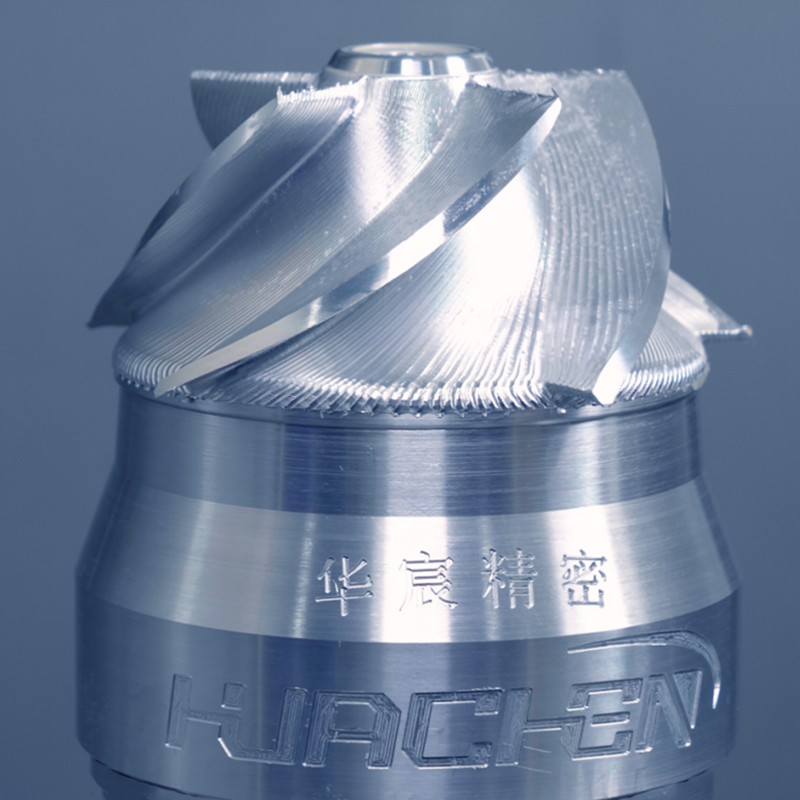

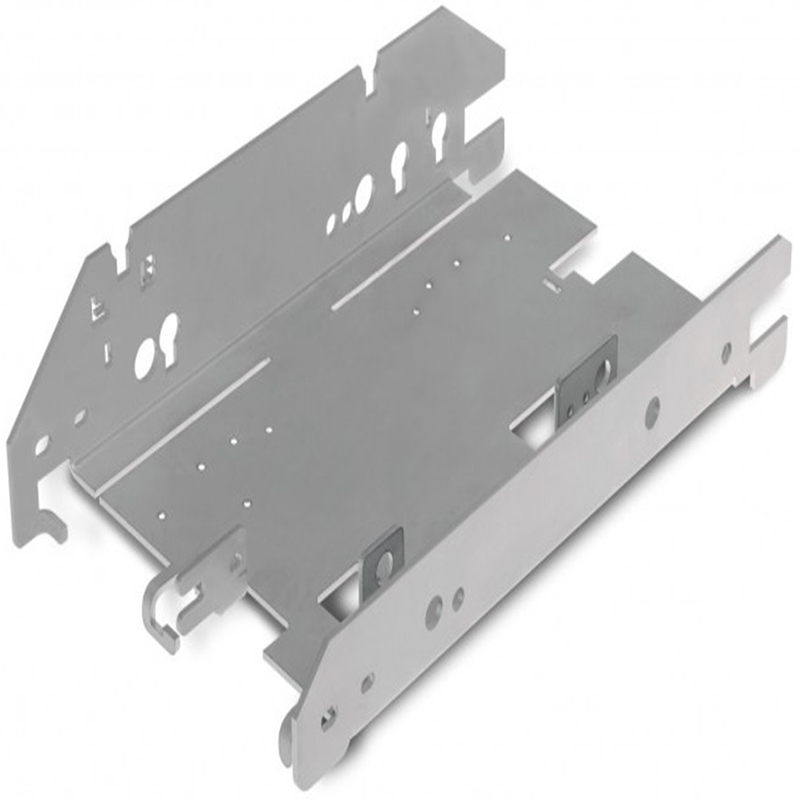

The high-precision laser vaporizes a cut line through the sheet metal, leaving a 90-degree high-quality cut-edge. Sheet metal bending is vital process in manufacturing industry, and is the plastic deformation of the work over an axis, creating a change in the part’s geometry. Similar to other metal forming processes, bending changes the shape of the work piece, while the volume of material will remain the same. In some cases bending technology may bring a small change in sheet thickness. For most operations, it will produce basically no change in the thickness. In addition to creating a desired geometric form, bending is used to impart strength and stiffness to sheet metal, to change a part’s moment of inertia, for cosmetic appearance and to eliminate sharp edges. The production of prototyping sheet metal parts consists of shaping a sheet of metal (foldable material obtained by laser cutting) to give it the desired shape and appearance. We perform the different operations of shaping and folding, punching, stamping and assembly by welding. Various different finishes can be applied (painting, anodizing, etc.). The use of these different processes depends on the selected material, the thickness of the sheet used (according to the desired application of your prototypes or small series) and the selected shape.

Application

Parts made from sheet metal prototypes are generally cut a budget relative to parts obtained by die-casting or be not able to be produced by CNC machining. The metal sheet can be worked rapidly into almost all shapes and with small or very large dimensions (from a simple bracket to the fuselage of a plane). For prototypes, these parts can, therefore, be used in a wide range of industries such as construction, automotive, furniture, medical, consumer products, electronics and so forth, and examples of common applications include hoods, metal enclosures, welded assemblies, chassis, boxes, and cabinets, etc. Our factory specialized in various of metal parts machining, include tube fabrication, Laser cutting, machining,deep drawing, stamping, bending, welding, riveting, plating, painting, powder coating, assembly etc.

Product detail pictures:

Related Product Guide:

We know that we only thrive if we can easily guarantee our combined cost competiveness and high-quality advantageous at the same time for China wholesale Sheet Metal Fabrication - Laser Cutting Machining Punched Bending Welding Stamping Plate Parts – Huachen , The product will supply to all over the world, such as: Kuala Lumpur, Holland, Ottawa, At Present, our products have been exported to more than sixty countries and different regions, such as Southeast Asia, America, Africa, Eastern Europe, Russia, Canada etc. We sincerely hope to establish wide contact with all potential customers both in China and the rest part of the world.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

-

Top