What is Vacuum Casting/Urethane Casting?

Polyurethane vacuum casting is a method for making high-quality prototypes or low volumes of parts formed from cheap silicone molds. Copies made in this way show great surface detail and fidelity to the original pattern.

Huachen Precision offers a complete turnkey solution for creating master patterns and cast copies based on your CAD designs.

We not only make high-quality molds but we also offer a full line of finishing services including painting, sanding, pad printing and more. We’ll help you create parts for showroom quality display models, engineering test samples, crowdfunding campaigns and more.

Advantages Of Vacuum Casting

Great for Low Volumes

Vacuum Casting is an excellent option for producing low-volume quantities of your part within 1 to 100 pieces. The average silicone mold will make around 12-20 parts, depending on the material and geometric complexity, and cast parts are very accurate and highly repeatable.

Rapid Turnaround

Soft Silicone mold tools can be made in as fast as 48 hours. Depending on the part size, complexity and volume, First Part Polyurethane vacuum casting can make up your parts, finish, ship, and deliver in as fast as 7 days.

Self-Coloured Parts

Vacuum casting is capable of making high-quality parts with the most intricate details. The excellent color and cosmetic finish are achievable without post-processing.

Durability and Strength

Vacuum Casting parts are significantly stronger than their 3D printed counterparts. Also, because cast urethane parts are made from rigid and flexible production-grade plastics, they have an equal, if not more strength, relative to Injection molded parts.

Low Upfront Investment

Silicone molds are significantly more affordable and quicker to make than the tooling used for injection molding, resulting in a lesser cost of production and cost-per-part. It is perfect for engineering models, samples, and rapid prototypes to production.

Material Diversity

Many types of polyurethane resins are available for casting, including rubber, silicone and overmolding.

Vacuum Casting Processes

There are three steps to making polyurethane vacuum cast parts: making the master pattern, making molds and casting the parts.

Step 1. Master Patterns

Patterns are 3D solids of your CAD designs. They are usually made by CNC machining or with 3D plastic printing such as SLA/SLS. You can supply your own patterns or we can make them for you. Patterns need to be able to withstand heating to 40°C.

Step 2. Making Molds

Casting molds are made from liquid silicone. This silicone is poured around the master pattern inside of a casting box, and then allowed to cure in an oven for 16 hours. Once dried, the mold is cut open and the master removed, leaving behind an empty cavity in the exact negative shape of the original.

Step 3. Casting Copies

Your choice of casting resins can now be poured into the empty cavity to create a highly accurate copy of the original. It’s even possible to overmold with two or more materials. Silicone molds are typically good for 20 or so copies of the master pattern.

Vacuum Casting Materials

Hundreds of casting polymers are commercially available to reproduce any conceivable hardness and surface texture. It is also possible to make parts that are fully opaque, translucent or completely transparent depending on your application. See more information on available materials as below:

Vacuum Casting Material Including(Similar PU)

Transparent PU, Soft plastic PU, ABS, PP, PE, Polycarbonate PU. We purchase PU material from Hei-Cast Company, Axson and BJB company

Vacuum Casting Polyurethanes Resins

| Material | Supplier | Material Simulation | Strength Shore | Flexion(PMA) | TC Max | Product color description | Advantage Disadvantage | Shrinkage |

| ABS TYPE | ||||||||

| PU8150 | Hei-Casting | ABS | 83 shD | 1790 | 85 | Amber, White and Black | Good Resistance | 1 |

| UP4280 | Axson | ABS | 81 shD | 2200 | 93 | Dark Amber | Good Resistance | 1 |

| PX100 | Axson | PS chocs | 74 shD | 1500 | 70 | White/Black | Ideal | 1 |

| POLYPRO TYPE | ||||||||

| UP5690 | Axson | PP | 75-83 shD | 600-1300 | 70 | White/Black | Good Resistance | 1 |

| COLORABLE ELASTOMER | ||||||||

| PU8400 | Hei-Casting | Elastomer | 20-90 shD | / | / | Milky white/Black | Good Bend | 1 |

| T0387 | Hei-Casting | Elastomer | 30-90 shD | / | / | Clear | Good Bend | 1 |

| HIGH TEMPERATURE | ||||||||

| PX527 | Hei-Casting | PC | 85 shD | 2254 | 105 | White/Black | High TC105° | 1 |

| PX223HT | Hei-Casting | PS/ABS | 80 shD | 2300 | 120 | Black | Ideal TC120° | 1 |

| UL-VO | ||||||||

| PU8263 | Hei-Casting | ABS | 83 shD | 1800 | 85 | White | 94V0 Flame Retarding | 1 |

| PX330 | Axson | Loaded ABS | 87 shD | 3300 | 100 | Off White | V 0 far 25 | 1 |

| CLEAR | ||||||||

| PX522HT | Axson | PMMA | 87 shD | 2100 | 100 | Clear | Coloration TG100° | 0.996 |

| PX521HT | Axson | PMMA | 87 shD | 2200 | 100 | Clear | Coloration TG100° | 0.996 |

Vacuum Casting Tolerances

The finished dimensions of vacuum cast parts are dependent on the accuracy of the master pattern, the part’s geometry and the type of casting material used. Generally a shrinkage rate of 0.15% is to be expected.

Finishing

As manufactured

Vacuum casted parts are cleaned post-casting and left as manufactured. Since polyurethane parts have a high level of smoothness and cosmetic appearance, a standard finish in any chosen color is often the case for casted parts.

Custom

An array of custom finishes are also available ranging from texturing and insert installation as post-processing options for your casted parts.

The most common surface finishes are:

· Glossy smooth finish

· Smooth Matte finish

· Rough finish

· Polished metallic finish

· Structured finish

Spray Painting

Castings can be painted with several automotive-grade paints to beautify and enhance its natural cosmetic appearance. Painting may be wet painting or powder-coating, sprayed or baked.

Silk Screen

Silk screening is a printing technique available for your vacuum casted parts. It involves the use of a mesh to transfer ink of logos, text, or graphics unto the surface area of your parts.

Vacuum Casting Parts Showcase

Custom Rubber Phone Shell

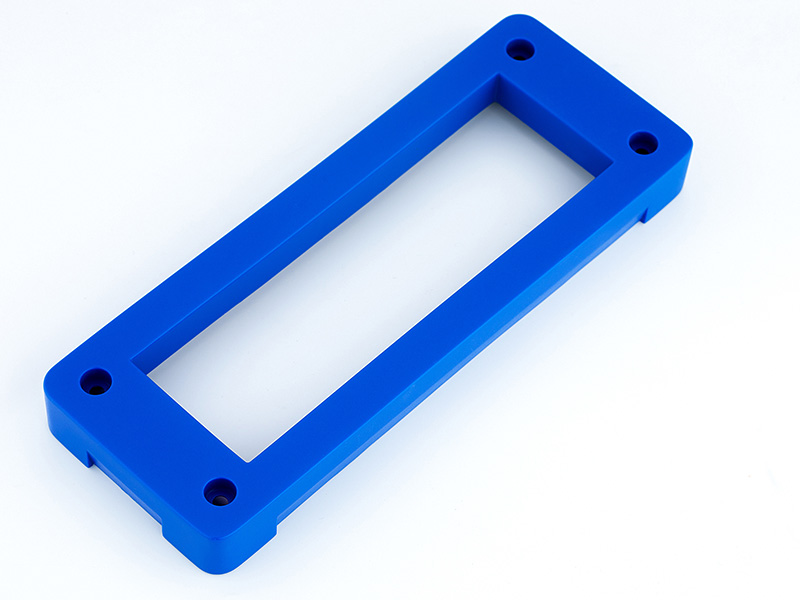

POM OEM Molds

Overmold Parts

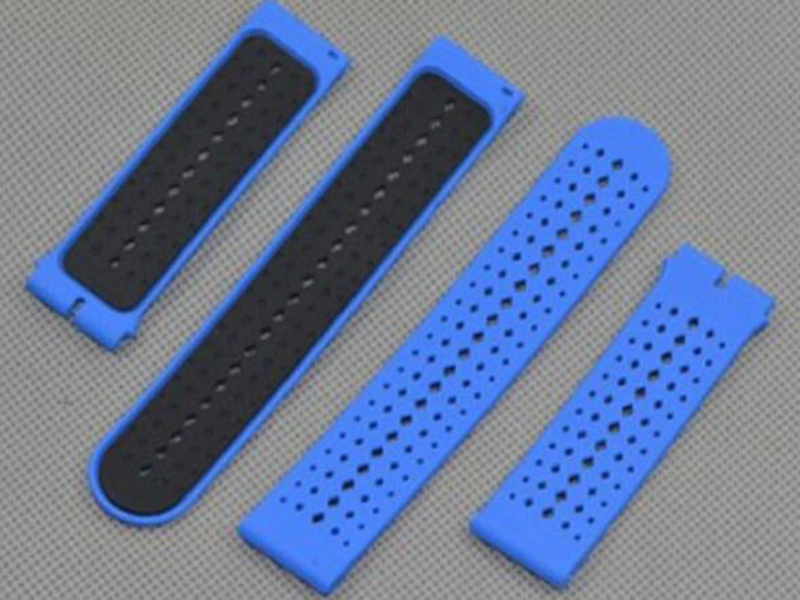

Sh40-A Rubber Watch Strap

Small Batch Urethane Casting Parts