CNC milling and turning are versatile, cost-effective and accurate, yet the possibilities for CNC machined parts expand even further when additional finishes are considered. What are the options? While that sounds like a simple question, the answer is complex because there are so many factors to consider.

Prototype Projects

First, what is the finish for? Is it to improve aesthetics or performance? If the latter, what aspects of performance need to be improved? Corrosion resistance, surface hardness, wear resistance or EMI/RFI shielding? These are just some of the questions to be answered so, assuming the designer knows what the goals are, let us take a look at various options.

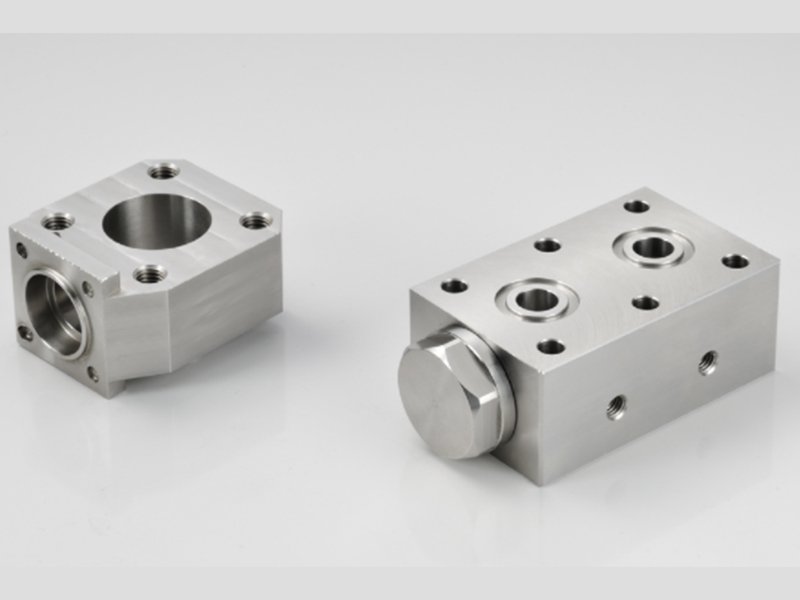

Finishes for CNC Machined Metal Prototype Parts

Over the past 40 years, Prototype Projects’ machinists have been asked to produce parts from a vast array of metals for applications in many industries. The products are regularly deburred, cleaned and degreased, however, the choice of finishes is very broad.

Today, our customers’ most popular metals are aluminium alloy 6068, stainless steel 304 and stainless steel 316. In fact, these three are so frequently requested that we hold stocks of them in various sizes to meet the needs of our three-day Express CNC machining service.

Still popular but specified less often are copper, brass, phosphor bronze, mild steel, tool steel. From time to time, customers request sepcial metals. If we can source the material and machine it in-house, we will do so, otherwise we usually subcontract the work to a specialist selected from our network of trusted machine shops. For example, exotic alloys like Inconel, Monel and Hastelloy tend to require particular techniques and tooling, so we usually outsource this.

Metal can be finished in many different ways. For example, aluminium can generally be clear anodised, hardcoat anodised, or black or colour anodised. The choice depends on whether the requirement is to enhance the aesthetics or the performance (specially corrosive resistance or wear resistance).

Stainless steel is inherently corrosion resistant but sometimes customers specify additional finishes. Electropolishing, for example, produces a high-quality finish as well as deburring and removing edges from intricate parts. On the other hand, if surface hardness, wear resistance or fatigue performance need to be improved, both 304 and 316 stainless steel can be nitrocarburised or nitrided.

Mild steel benefits from perhaps the broadest choice of finishes. Options include wet painting, electrophoretic painting, powder coating, electroplating, chemical blacking, electropolishing, hardening, titanium nitriding (TiN) coating, nitrocarburising, and bead blasting, etc.

Copper and brass are usually specified for functional parts, with no further finishing required after machining. If necessary, however, parts can be polished manually, electropolished, electroplated, vapour blasted, lacquered or treated with chemical blacking.

The finishes outlined above are not the only ones available for metal and alloys. We are always happy to discuss finishes with customers and we endeavour to help wherever we can.

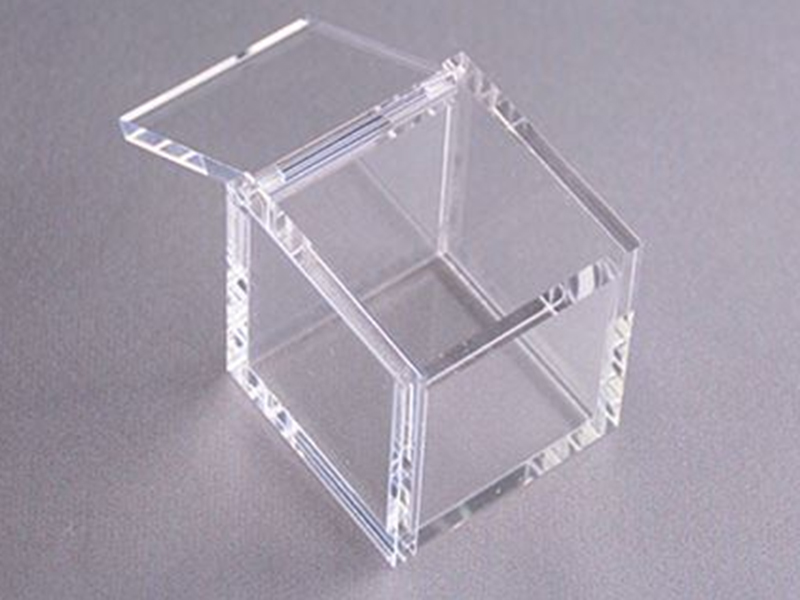

Finishes for CNC Machined Plastic Prototype Parts

As with metal aparts, all of the plastic parts we CNC machine are basically deburred, cleaned and degreased but, after that, the surface options tend to be different.

As the majority of customers request CNC machined prototype plastic parts in either acetal (black or natural) or acrylic, we hold kinds of material in stock. Acetal does not readily accept additional finishes, so parts are normally supplied ‘as machined’.

Acrylic, being clear, is often polished to a transparent appearance. This can be done manually with successively finer grades of abrasive, or with flame polishing. As per one's request, acrylic can be painted with acrylic paint or vacuum metallised to achieve a highly reflective surface.

Some of these are easier to finish than others, so you are always welcome to discuss materials and finishes with us. Regarding plastic, we can sand, prime and paint parts, polish them (manually or by flame), electroless plate or vacuum metallise. For some plastics with low surface energy, specialist surface preparation with primer or plasma treatment is necessary.

Dimensional Inspection of CNC Machined Prototype Parts

One reason why customers choose to have prototype parts CNC machined rather than 3D printed is the higher accuracy. Our quoted tolerance for CNC machined parts is ±0.1mm, though dimensions are normally held to much tighter tolerances, being subject to the structure, material, and geometry. We strictly inspect dimensions, of course, customers can also ask for specific features checked.

Often the measurements can be taken with handheld callipers or micrometers but our co-ordinate measuring machine (CMM) is ideal for more thorough inspections. This takes time and is not available with our advanced CNC service but it is quicker than sending the parts to a third-party for CMM inspection. The only exceptions are when a comprehensive, fully-programmed CMM inspection routine is required, or a batch of parts has been machined and 100 per cent inspection is required.

Assembly Options for CNC Machined Prototype Parts

One reason is customers choose to have prototype parts CNC machined rather than 3D printed is the higher accuracy. The allowable tolerance for CNC machined parts is ±0.1mm, though dimensions are normally held to much tighter tolerances, depending on the material and geometry. We will strictly inspect all parts before shipment, and customers can also ask for specific features to be checked as well.

Often the measurements can be taken with handheld callipers or micrometers but our co-ordinate measuring machine (CMM) is ideal for more thorough inspections. It is quicker than sending the parts to a third-party for CMM inspection. The only exceptions are when a comprehensive, fully-programmed CMM inspection routine is required, or a batch of parts has been machined and 100 per cent inspection is required.

Post time: Jun-30-2022