There are thousands of materials in the market, but do you know how to choose the suitable material? And do you know how to find the best material for your CNC prototype parts? If you’re in this difficult situation, you will find to select the appropriate material for your product is restricted by many factors. A basic principle that needs to be followed is: the performance of the material must meet the various technical requirements and the environmental requirements of the product .

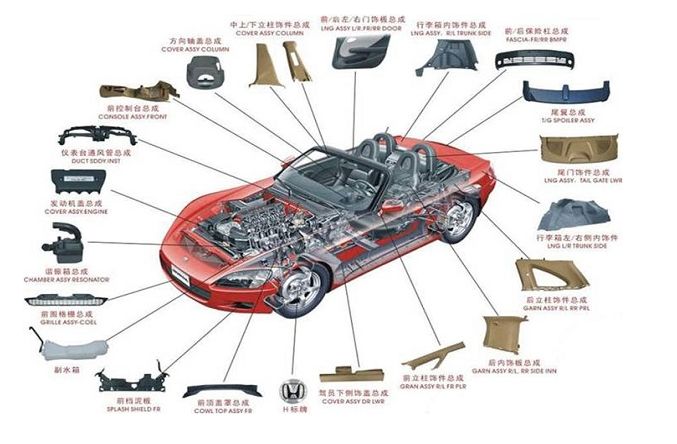

When you are choosing materials for mechanical parts, CNC Prototyping Parts, Fast Prototyping, Hardware Prototyping, new energy cars, you could consider the following 4 aspects:

1)Material Rigidity

Rigidity is the primary consideration when selecting materials, because the precision parts needs certain stability and wear resistance in in practical work, and the rigidity of materials determines the feasibility of the product design. More rigidity means the material is less likely to deform under external forces. According to the characteristics of the industry, #45 steel and aluminum alloy are usually selected for non-standard tooling designs; #45 steel and aluminum alloy are also used more for custom parts machining; aluminum alloy is mostly used for Automotive Prototype designs.

2)Material stability

For a product with the high precise requirements, if it is not enough stable, the various deformation will be occurred after assembly, or deformed again in the process of using. In short, with the change of temperature, humidity and vibration and other environment in constant deformation, which is a nightmare for the product.

3)Materials ’machinable

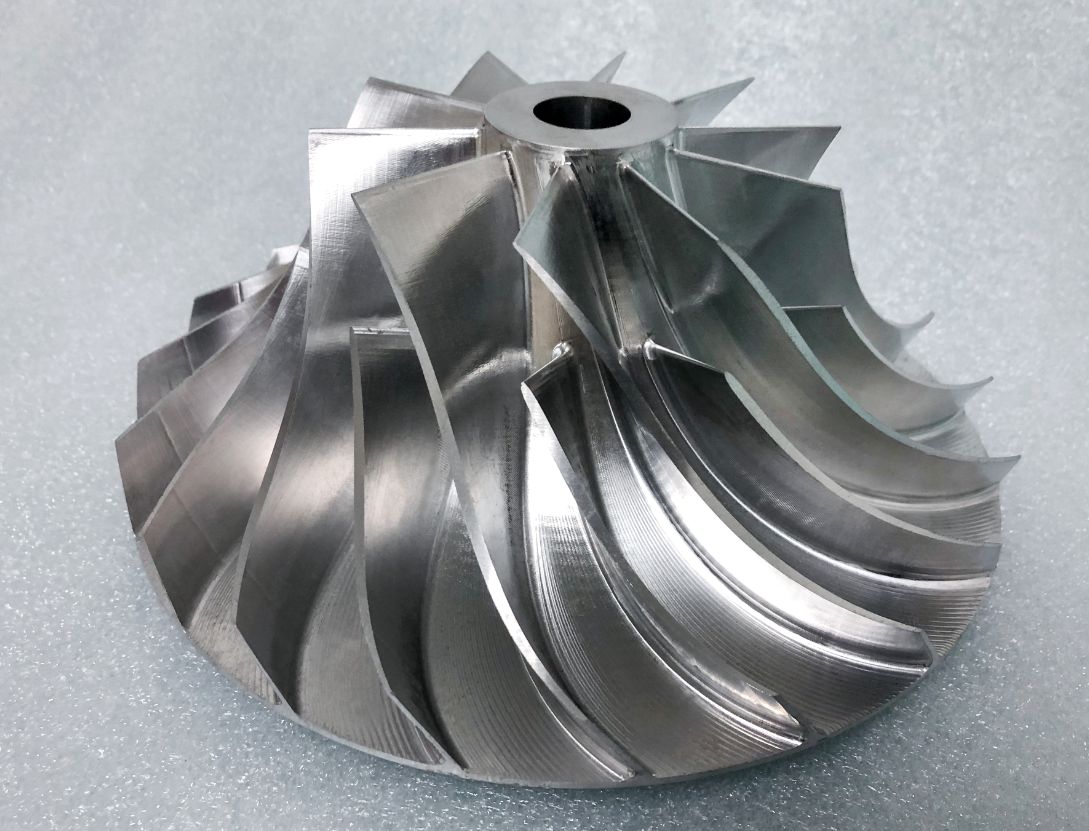

The machining property of materials determines whether the part is easy to machine or not. Compared with aluminum alloy prototype parts, stainless steel material has a higher hardness and is relatively more difficult to process. Because it is easy to cause tool wear during processing. For example, machining some small holes in stainless steel parts, especially threaded holes, it is easy to break the drils and cutting toolings, also easy to break the screw tap, which will lead to a very high machining cost.

4)Material cost

1.Cost is an important consideration in selecting materials. In a circumstance of fast-growing AI technology and well-popular new energy, how to choose the best material to save the cost and save the time to enter into the market that becomes a prevailing trend ! For example, Titanium alloy has a light weight, the high specific strength and good corrosion resistance. It is widely used in new energy automobile engine systems and plays an immeasurable role in energy saving and consumption reduction. Despite the superior properties of titanium alloy parts, the main barrier that led to its widespread using in the new energgy automotive industry is the high cost. You could choose a cheaper material if you don't have to have it.

Wrong materials, all in vain! Please be careful to choose your material, If you donn’t know how to choose, please feel free to contact us, we are online all the time, thank you!

Post time: Apr-19-2023