When quoting prototype projects, it is necessary to select appropriate processing methods according to the feature of the parts in order to complete the prototype projects faster and better. Now, it is mainly engaged in prototype processing, lathe processing, 3D printing, filming, fast molds, etc. Today we will talk about the difference between lathe processing and 3D printing.

First of all, 3D printing is a material increased technology, and lathe processing is a material reduced technology, so they are very different in materials.

1. Differences in materials

Three-dimensional printing materials mainly include liquid resin (SLA), nylon powder (SLS), metal powder (SLM), gypsum powder (full-color printing), sandstone powder (full-color printing), wire (DFM), sheet (LOM), etc. Liquid resin, nylon powder and metal powder occupy the vast majority of the industrial 3D printing market.

The materials used in lathe processing are all plates, which are plate-like materials. By measuring the length, width and height to wear of the parts, the plates are cut for processing. The material ratio of lathe processing is 3D printing. In short, hardware and plastic plates can be processed by lathe, and the density of the molded parts is higher than that of 3D printing.

2. Differences in parts due to the forming principle

As we mentioned earlier, 3D printing is a kind of additive manufacturing. Its principle is to cut the model into N layers/N multi-points, and then stack them layer by layer/point-by-point in order, just like building blocks. Same. Therefore, 3D printing can effectively process and produce parts with complex structures, such as hollow parts, while CNC is difficult to realize hollow parts processing.

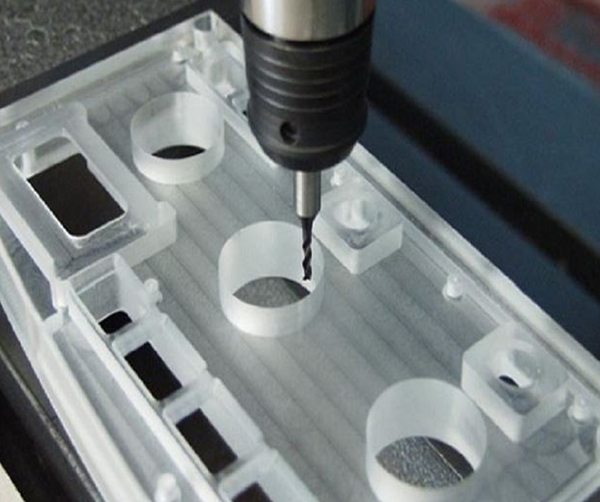

CNC is the way to reduce material processing. Through high-speed operation of various tools, the required parts are cut out according to the programmed knives. Therefore, lathe can only have rounded corners of a certain arc, but can not directly process right angles, which can be realized by wire cutting/spark technology. External right-angle lathe processing is no problem. Therefore, the internal right-angled parts can be considered to choose 3D printing processing and production.

If the surface area of the part is relatively large, it is recommended to choose 3D printing. Lathe processing of the surface is very time-consuming, and if the programming and operating machine masters are not experienced enough, they cannot leave clear patterns on the parts.

3. Differences in operating software

Most of the 3D printing slicing software is easy to operate, even a layman can use the slicing software proficiently for a day or two under professional guidance. Because the slicing software is very easy to optimize, the support can be automatically generated, which is why 3D printing can reach individual users. CNC programming software is much more complicated and requires professionals to operate it.

4. Differences in post-processing

There are not many options for three-dimensional printing parts after processing. Generally, they are polished, sprayed, deburred, and dyed. In addition to the above mentioned, there are electroplated, silk screen printed, printed, anodized, laser engraved, sandblasted, etc. The above is the difference between our CNC lathe processing and 3D printing. Because the programming is very complicated, a component can have multiple CNC machining schemes, and 3D printing will only be relatively objective due to the placement of a small part of the processing time consumables.

Post time: May-12-2022