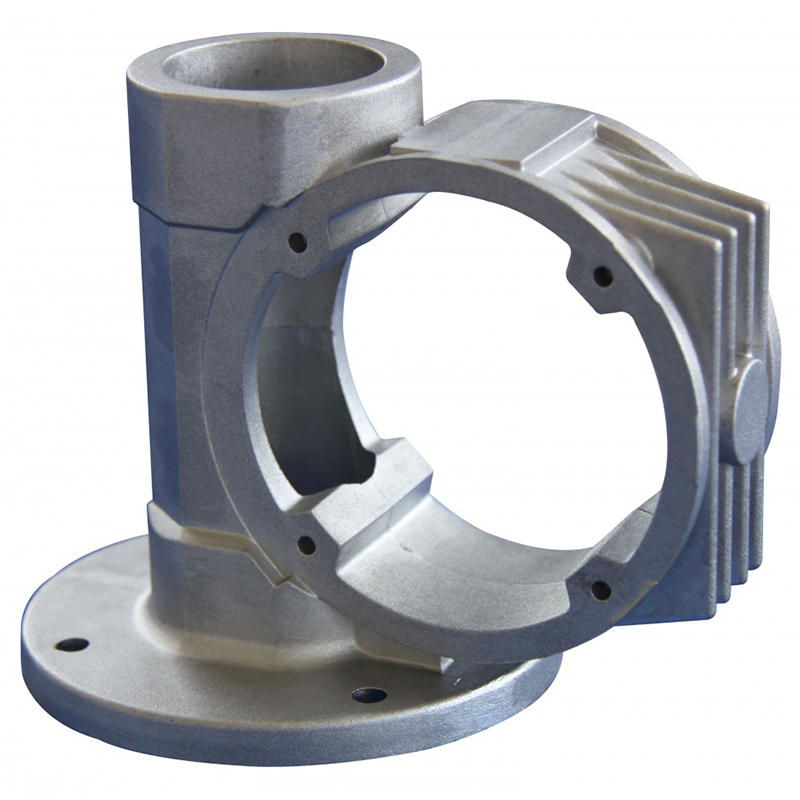

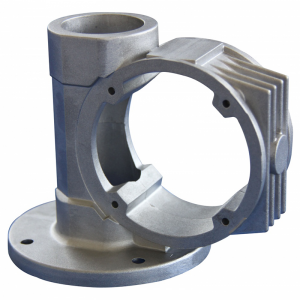

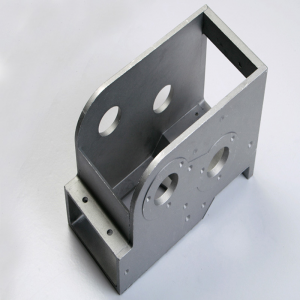

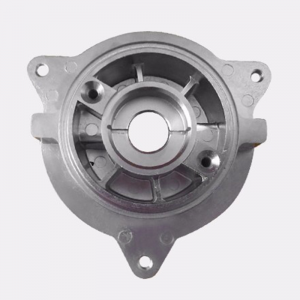

OEM Metal Die Casting Process Sample Production

Details

|

Item |

Description |

|

Process Technology |

The lost wax casting process The soluble glass casting process Silica casting process Die casting process Sand casting process plus Precision CNC Machining Surface Treatment |

|

Available Material |

(1) grey iron, ductile iron, pig iron |

|

(2) carbon steel, stainless steel, alloy steel |

|

|

(3) aluminum alloy, aluminum, A380, aluminum 6061 |

|

|

(4) zinc alloy, copper, brass, bronze etc |

|

|

Weight Range |

0.02-50 KGS |

|

MOQ |

500 Pieces |

|

Tolerance |

±0.02mm |

|

Testing |

Three coordinate measurement machine for testing. |

|

Certification |

ISO9001:2015 |

|

Standard |

ISO, DIN, AISI, ASTM, BS, JIS, etc. |

OEM Material

Investment casting: ASTMA148-class80-40, ASTMA148-class80-50, A572GR60, AISI316, Stainless Steel, ST52, S355, GS-52.3, ASTMA48-class30B, CK45, 1.7218-25CrMo4

Sand Casting:GGG50, GGG30, ASTMA48-class25B, 42CrMo4, C22, Ductile iron65-45-12, AlCuMgpbF34, EN-JIS-500-7, EN1563, EN10293-GE300, HT200, DIN17205-GS-25CrMo4

Die Casting:C1040, A356, A380, AISI12

Advantages of Metal Die Casting

1. It can make metal parts with complicated shapes, clear outlines, thin walls and deep cavities.

2. Die casting has high dimensional accuracy and good interchangeability.

3. High production efficiency and mass production.

4. Easy-to-use mosaic pieces.

5. High material utilization rate.

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

-

Top