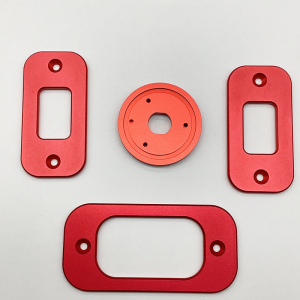

Precision Custom Metal Anodized Multi-Colors Parts

Why Metal Components Need Finishing Treatments?

1. It increases the corrosion resistance of the metal

Corrosion is a significant destroyer of metal parts and their surfaces. Rusts on metal surfaces reduce the quality of such components, and they won’t be able to perform their functions adequately. Most of the metal machined surface finish examples target corrosion resistance. A correctly done machining surface finish ensures adequate protection of the metal. Therefore, you can be sure that it will last longer.

2. It enhances the aesthetics of the metal

Some clients place aesthetics as highly as the performance of the product. This is because the appearance of your product says a lot about it. With the various metal surface finishes available, your CNC machined parts will look as good as they can.

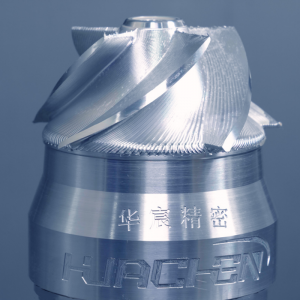

3. It eases the manufacturing process

A properly done machining surface finish will make manufacturing much easier. For example, a sandpapered or brushed surface adheres better to paints. This helps to relieve the manufacturer’s stress. General, surface finishes on CNC machined parts:

Improves metal conductivity

Increases wear resistance

Minimizes friction effects on the metal

Increases the strength of the materials

Protects the metal from chemical attacks

Improves the rust-resistant properties of the metal.

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

-

Top