Mass Manufacturing Custom Injection Molding Plastic Products

Profession & Better

| Product Description | ODM plastic injection molding |

| Plastic Materials | ABS, Nylon6, Acrylic, PBT, PEEK, PLA, PPS, PVC, HDPE, PEI, PC-PBT, PPE-PS, PSU, LDPE, PET, TPE, TPV |

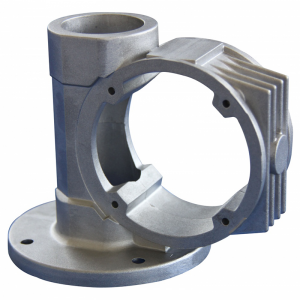

| Other Materials | Rubber, Silicone, Aluminum, Zinc, Copper, Metal, etc. |

| Feature | Non marking and Non flash |

| Standard | ISO9001-2015 |

| Export Country | Europe, Japan, America, Australia, UK, Canada, France, Germany, Italy, etc. |

| Experience | 10 years experience in plastic injection mold making and plastic products produce. |

| To Be Discussed | In-Mold Decoration, Injection Mould, Plastic Mold, Overmould, 2K Mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold, Collapsible Core Mold, Die Sets, Compression Mold, Cold Runner System LSR Mold, etc. |

| Mould Base | Husco Standard, European Standard, World Standard |

| Surface Finish | Texture(MT standard), High gloss polishing |

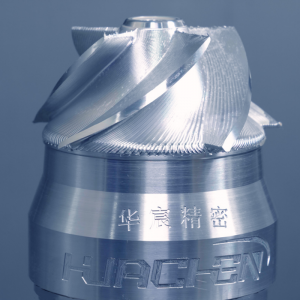

| Equipment | High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder |

Package

We are dedicated to delivering the most high-quality and beautiful parts to meet your expectations.

Three layers of protection are applied to the package

1. Wrapping paper

2. Foam

3. Paper/Wooden box

Advantages

Injection Molding has the most variable options for materials, colors and configurations when compared to CNC machining or 3D printing

1. Excellent production speed

2. Low cost per part

3. High precision

4. Excellent surface finishes

5. Exceptional strength

6. Multi-material manufacturing

Write your message here and send it to us

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

-

Top