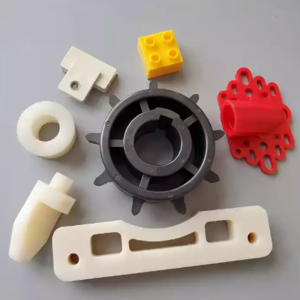

3D Printing Resin Model Prototype

An Elegant Artwork Solution

Parts printed using this technology mostly has applications in jewelry, footwear, industrial design, architecture, engineering, construction (AEC), automotive, aerospace, dental and medical industries, education, geographic information systems, civil engineering, firearms, and more.

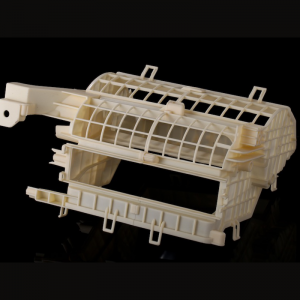

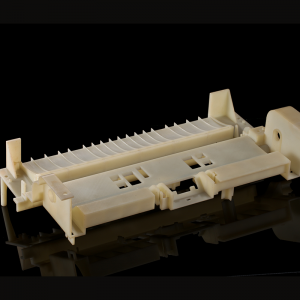

It is a technology that builds objects based on digital model files, using bondable materials such as powdered metal or plastic, and printing them layer by layer. The printed content comes from 3D models or other electronic data, and the printed 3D objects can have any shape and geometric characteristics.

From large resin parts to small resin parts, we offer products that leverage molding technology that meets customers’ needs. Moreover, printed parts are colored through a wide variety of decorative and plating technology that is attractive to customers.

We always provides the best processing service and qualities to clients. We have the most advanced 3D printers, like SLA/SLS/SLM/MJF-HP, industrial-grade CNC engraving, and projection molding machines to produce exquisite appearance models and functional prototypes. On the other hand, it provides post-3D printing processing services, including coloring, grinding, ash spraying, painting, sandblasting, silk screen printing, pad printing, UV oil, metal oxidation, wire drawing, electroplating and other review post-processing procedures. Many different technologies exist for 3D printing. They differ in the way the materials are available and build the parts in different layers.

Common materials for 3D printing include nylon glass fiber, polylactic acid, ABS resin, durable nylon material, gypsum material, aluminum material, titanium alloy, stainless steel, silver-plated, gold-plated, and rubber-like materials. As a single step manufacturing process, 3D printing saves time and therefore costs associated with using different machines for manufacturer.

3D printers can also be set up and left to get on with the job, meaning that there is no need for operators to be present the entire time. Therefore, it is cheaper than other RP processing ways.

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

-

Top